Under the general trend of global energy transformation, more and more manufacturer have begun to pay attention to sustainable development and intelligent production. An internationally renowned drinkware and food container manufacturer in Zhejiang Province is a typical representative of these manufacturer. In order to strengthen the production base, enhance synergy with customers, and expand international market share, the company invested in a new modern production plant in Pluak Daeng, Rayong Province, Thailand. As a highly automated manufacturer, any power outage will directly affect large-scale production output and even cause immeasurable losses. To ensure the continuous and stable operation of the production line, the company decided to use the abundant local sunlight resources to install a photovoltaic power station on the roof of the factory to provide stable energy supply.

However, with the planning of photovoltaic power stations, company gradually realized new challenges. Thailand's long period of high temperature weather brought additional safety risks to the power station. The long high temperature environment brought a massive "baking" test to the equipment, and it could also cause equipment overheating, failure, and even fire accidents. For manufacturing companies that rely on highly automated and expensive equipment, any power outage or accident will have a serious impact on production and property. In addition, traditional power station systems lack smart energy management capabilities. When problems occur in the PV power plant, it is difficult to respond in time and accurately troubleshoot faulty modules, which not only affects the factory's operating efficiency, but also may increase the risk of production line interruptions. To ensure that its production line can operate efficiently and reduce potential risks, the factory urgently needs a safe, smart, and efficient power station energy management solution.

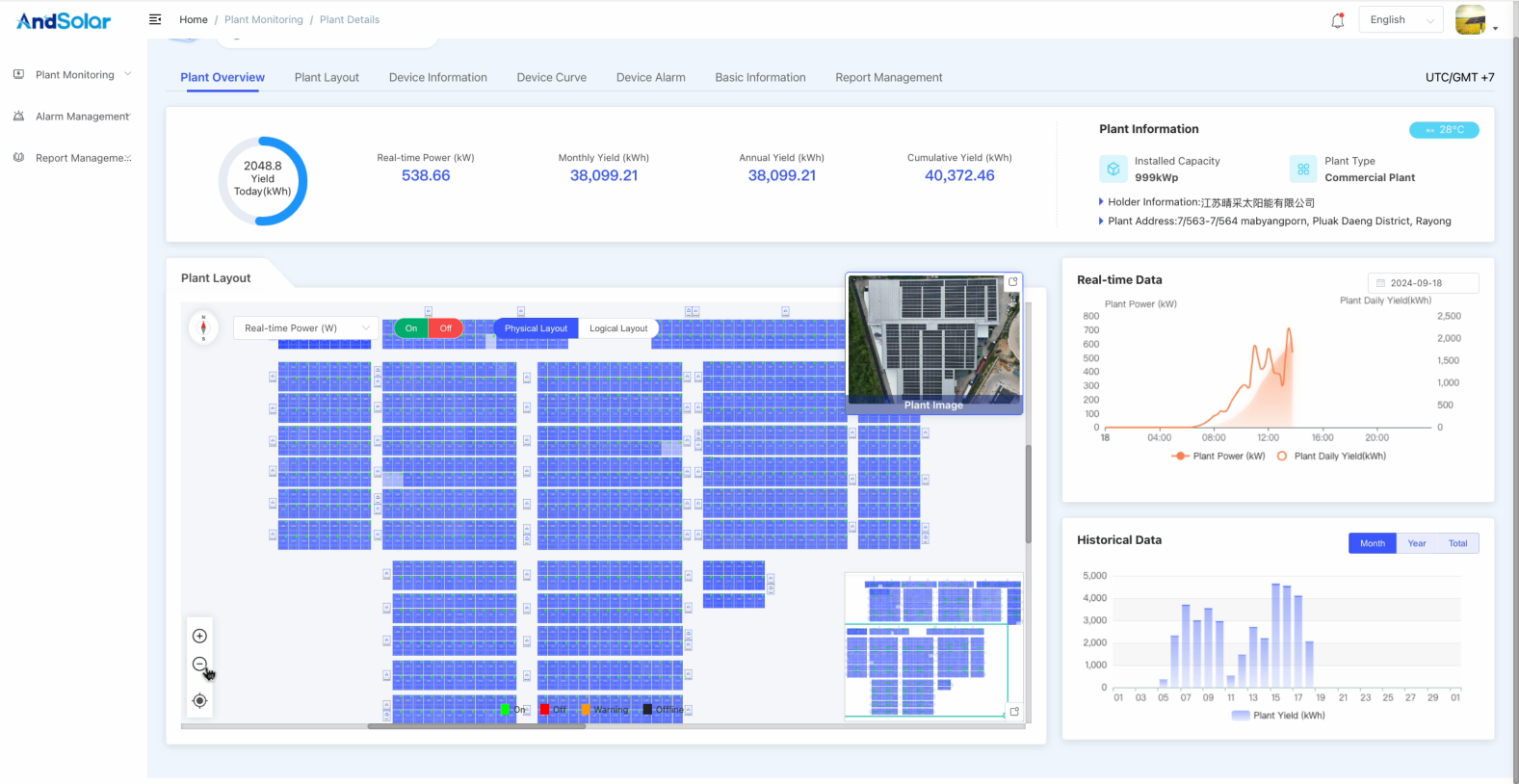

Based on the above requirements, the company finally chose the smart energy solution of AndSolar. The installed capacity of this project is 1 MW , and a total of 900 units of Smart RSD AMCL and 16 transmitter ADCU are used, which comprehensively improves the safety and management and operation efficiency of the power station.

The module-level smart RSD AMCL of AndSolar has the ability of rapid shutdown at the module level, which fully complies with the requirements of the local Thai regulations "Thai Electrical Code: Solar Rooftop Power Supply Installations 2022". In an emergency, the RSD can reduce the voltage of the photovoltaic system to below the safety standard of 80V within 30 seconds, thereby effectively preventing the risk of electric shock and ensuring the safety of factory employees and equipment. In response to the safety hazards caused by Thailand's long period of high temperature weather, the module-level smart RSD AMCL of AndSolar is designed with a variety of high-performance materials to effectively cope with high temperature environments. These materials meet the highest flame retardant grade V-0 in the US UL94 standard, greatly reducing the risk of fire spread(in the event of fire accident) and providing strong protection for the reliability of the power station. In addition, AMCL has three shutdown modes: high-temperature active shutdown, cloud platform remote shutdown, and on-site manual shutdown, ensuring timely response to emergencies in various scenarios.

Through the AndSolar Cloud Platform, the factory's photovoltaic power station has achieved full-life cycle monitoring at the module level, greatly improving the efficiency of operation and maintenance. The platform supports the generation of 1:1 virtual twin power stations, allowing to quickly locate faulty modules, increase the efficiency of power station operation and maintenance, and effectively reduce the risk of production stagnation caused by power station failures. Managers can view the real-time operation status of each module through the APP or Web-platform at any time and any place, including key data such as voltage, current, power, power generation and temperature , to ensure the comprehensive controllability and transparency of the power station. The platform's smart temperature sensor system helps users view the temperature of the equipment in real time. When the temperature reaches 75°C, the system issues an early warning; when it rises to 85°C, the active shutdown mechanism is triggered. In addition, customers can flexibly set personalized safety thresholds through the platform according to their region.

Through the smart upgrade of the photovoltaic power station, the customer not only greatly ensured the safety of the power station, but also achieved refined management of the power station through the AndSolar Cloud Platform, ensuring the overall income and asset operation management of the power station .

We are honored to provide safe, intelligent and efficient energy solutions for the drinkware and food container manufacturing industry . In the future, we will continue to develop more efficient and safer photovoltaic technologies to promote the global energy transformation process. We look forward to exploring new solutions for sustainable energy with partners from all walks of life and jointly promoting innovation and development in the energy industry .