DC High Voltage “Nemesis” in Photovoltaic Systems

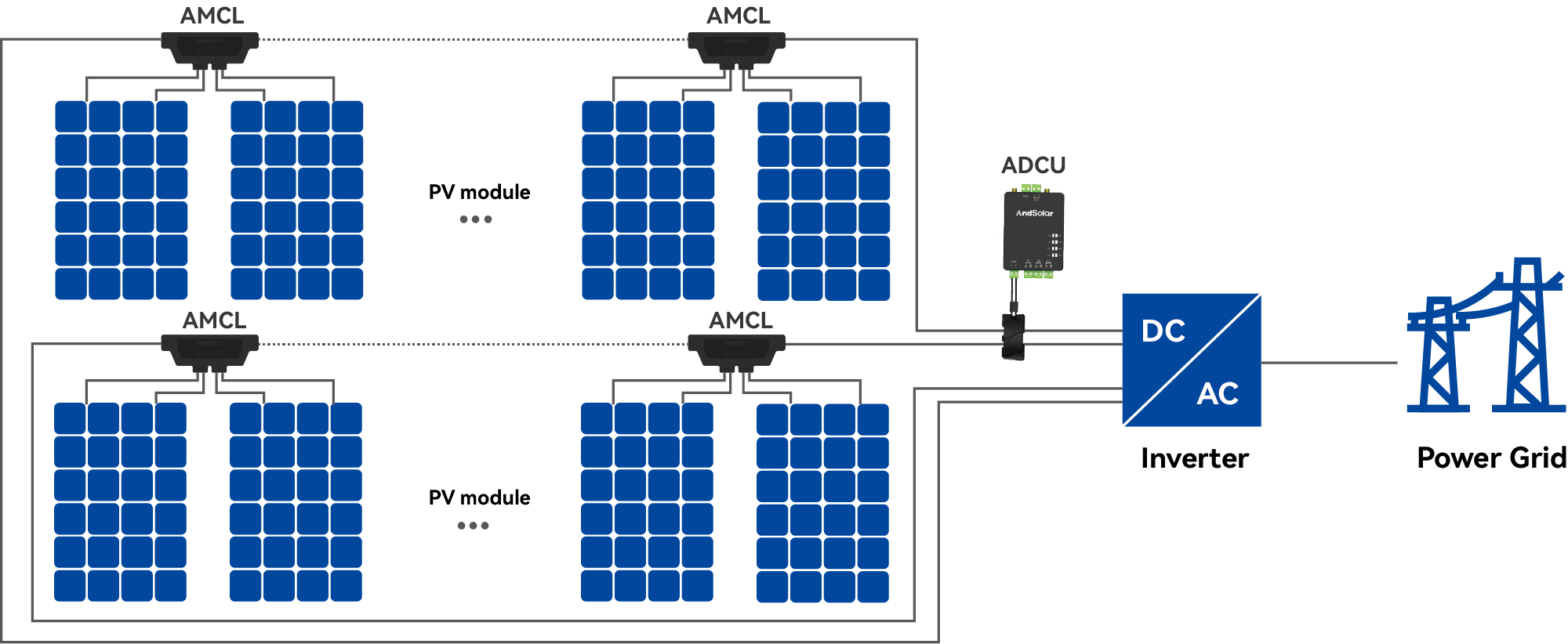

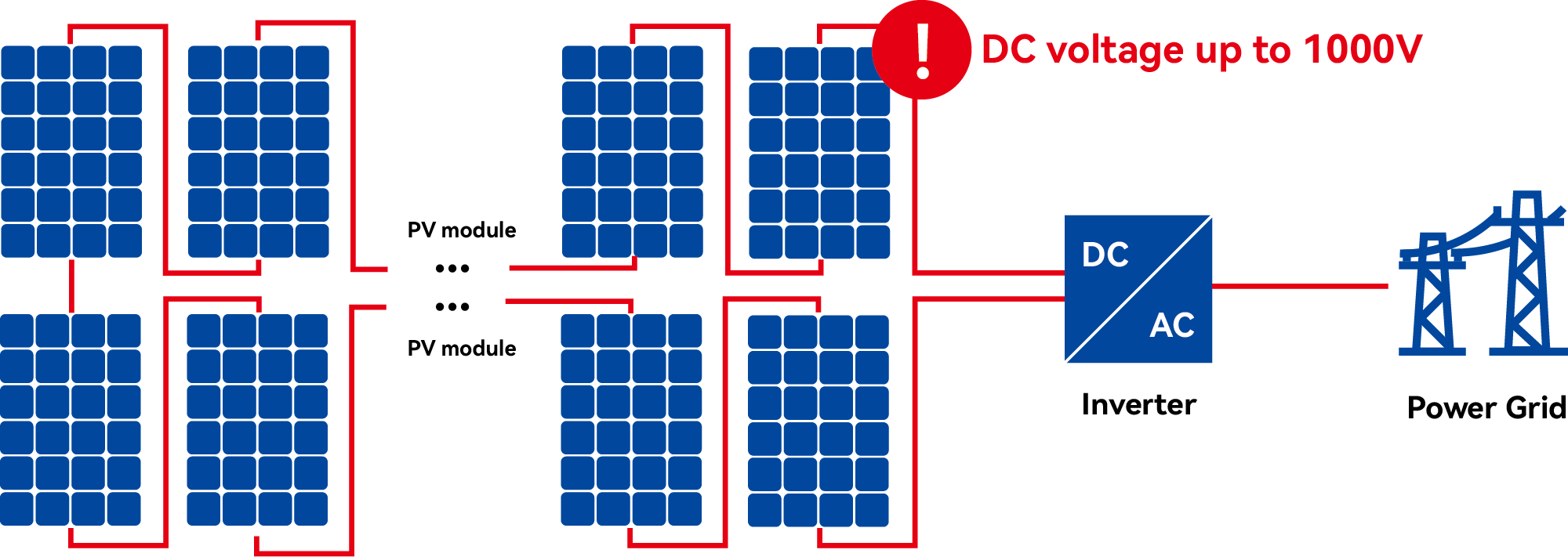

In PV system, PV modules are devices that convert solar energy into direct current(DC). They are usually connected in series to form PV strings, and then the direct current(DC) is converted into alternating current(AC) through an inverter. PV modules connected in series often form a DC high voltage in range of hundreds to thousands of volts.

DC voltage up to 1000V Inverter Power Grid

In a traditional PV system, we can only disconnect the PV system at the system or string level through an inverter or circuit breaker. However, due to the operation characteristics of PV modules, after disconnected, as long as the modules continue to receive sunlight, the DC high voltage will still remained within the strings. In Distributed PV scenarios, PV systems are often integrated with buildings or located near people's daily activities area. In this scenario, the fire safety requirements of PV systems will undoubtedly become more important. Whether there is a fire accident inside the building or the PV system catches fire due to some failure issue, a PV system that cannot perform low-voltage safety cutoff will seriously threaten firefighting, first aid and other operations. The personnel safety issue will lead to a more severe losses.

Implementing module-level rapid shutdown (RSD) in PV systems is the most direct and effective way to solve the above problems. RSD equipment can quickly disconnect each individual PV module in the system in case of an emergency situation, thereby eliminating DC high voltage in the system, thus improving system safety and ensuring the safety of personnel, property and provide better fire protection.

< AndSolar module level rapid shutdown solution >

The U.S. National Electrical Code (NEC ) is one of the most detailed electrical regulations regarding photovoltaic systems. It is implemented in the United States and many other countries. It is also the first regulation to include rapid shutdown of PV systems. It sets the distance to the PV system of 30cm as the array boundary. The photovoltaic system needs to have the ability to reduce the voltage within the array boundary to 80 V dc, and the voltage outside the array boundary to below 30 V dc, within 30 seconds, which means that the PV system needs to be disconnected at module level. From Chapter 690.12 of NEC 2014 which was the first regulation that put forward requirements for rapid shutdown of PV system , to NEC 2017&2020 version which updated this rapid shutdown requirement became mandatory and more complete, has made PV module level rapid shutdown become a key to ensuring the safety of distributed PV. At present, more and more countries and regions have incorporated similar requirements into their regulations or standards .

Following the promotion of PV module-level rapid shutdown standards globally, China's National Energy Administration has proposed the "Notice on Strengthening the Safety of Distributed PV Power Generation (Draft for Comment)" in November 2021, which clearly requires that PV modules to have safety shutdown protection feature. In addition, Beijing, Guangdong Dongguan, Guangdong Shenzhen, Zhejiang Haining and other places have also issued their own local standards or management measures, jointly emphasizing that PV projects must have module-level rapid shutdown capabilities to ensure the safety of personnel and property. This trend clearly shows that rapid shutdown at the PV module level is gradually becoming a global standard to ensure the safety of Distributed PV.

AndSolar Module-level Smart Rapid Shutdown Device

AMCL Series of smart rapid shutdown Products launched by AndSolar Technology Co., Ltd. (hereinafter referred to as AndSolar ) is not only would enable PV systems to have a basic rapid shutdown capabilities to meet the requirements of NEC regulations, but also would provide local, remote and fault-triggered auto shutdown capabilities and other shutdown methods, to ensure maximum system safety. In addition, the AMCL series products could also realize module-level positioning and monitoring, to realize the digitalization and smart PV power stations, to reduce O&M costs, and to realize various smart applications.

As a company that aim to keep improving PV system safety, AndSolar has always designed products with the most stringent safety and reliability standards. AMCL series RSD have passed UL1741 , UL3741 , IEC 62109-1, I EC 61000-6- 1/-2/-3/-4 and other related certifications. This article will also share with you the meaning behind these certifications.

UL1741 :

UL 1741 is the highest safety and electrical safety standard in North America for PV power generation equipment, including inverters, power converters, controllers and connection equipment . At the same time, this standard also focuses on the relevant requirements for the definition of rapid shutdown in the NEC regulations. In order to ensure the reliability of the product, AndSolar entrusted the authoritative third-party testing and certification agency CSA to inspect the hardware design , software design, functional safety, and product reliability of the AMCL series of smart RSD products in accordance with the UL1741 standard under various extreme and harsh conditions. It has been tested in many aspects, and successfully passed the all-round evaluation of the standard, and obtained the certification of this standard, which represents the highest requirements for RSD. It also proves that the AMCL series products comply with the regulatory requirements of NEC 2017&2020.

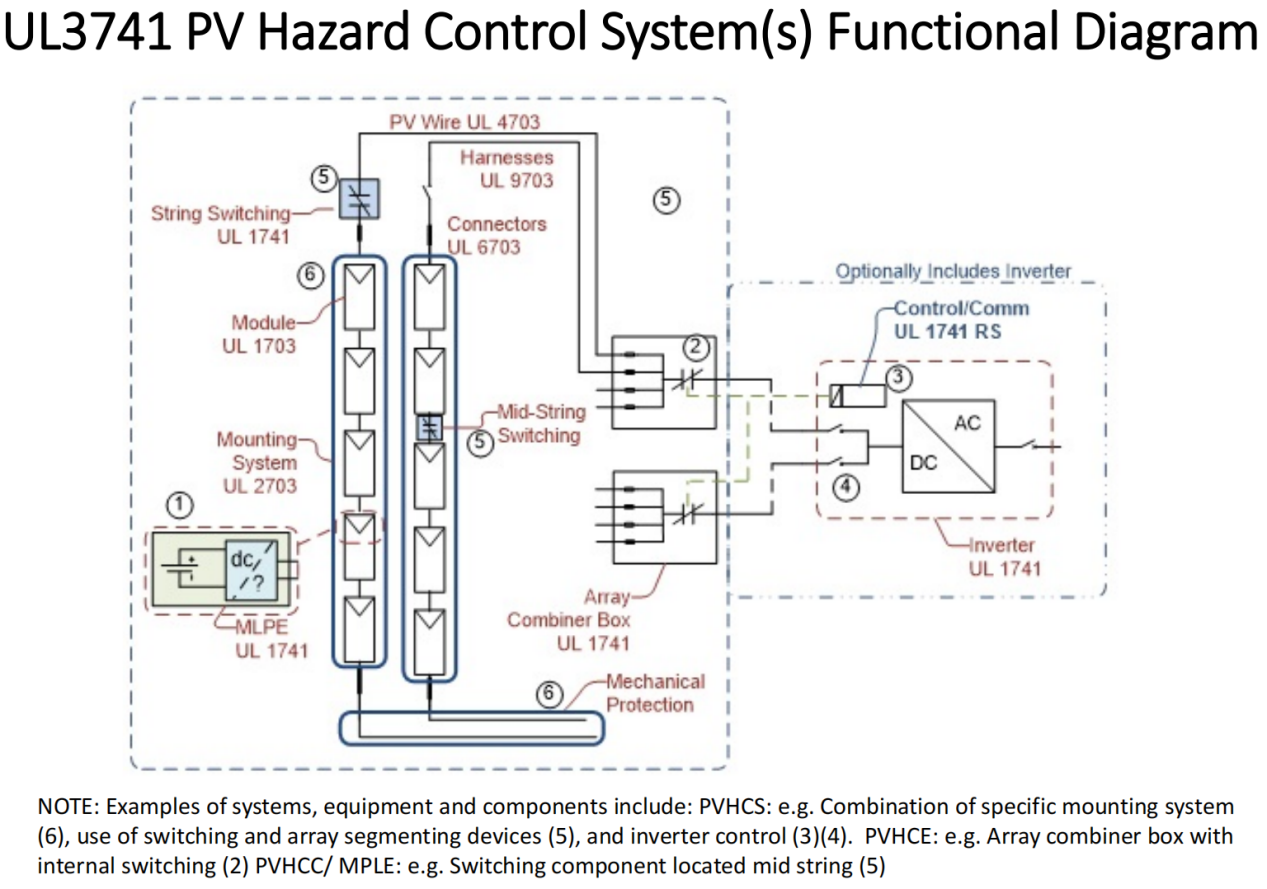

UL3741 :

Standard For Safety: Photovoltaic Hazard Control, issued in December 2020, this standard proposes the concept of "PV hazard control system". Firefighters might be exposed to electrical hazards due to damage to PV equipment when operating in PV-related buildings, and since PV-related system may consist of a series of equipment from different manufacturers. The UL3741 standard will produce a PV hazard control equipment list (PVHCE) for PV system evaluation. The characteristics of these equipment and the operational integrity of maintaining hazard control functions will be used as evaluation items. In order to obtain UL 3741 certification, AndSolar added AMCL series products to the entire photovoltaic system and passed a series of tests or evaluations, which further ensured that Heguang Tongyao products can ensure the safety of the entire photovoltaic system.

IEC 62109-1 :

Safety of power converters for use in photovoltaic power systems –

Part 1: General requirements, Safety of power conversion equipment in photovoltaic power systems - Part 1 - General requirements, as an access requirement for photovoltaic power electronic devices, stipulates corresponding safety requirements, including: electrical safety, mechanical safety, thermal safety, fire prevention and other parts, among which electrical safety mainly focuses on safety measures such as insulation, grounding, and anti-electric shock protection of electrical equipment to prevent the occurrence of electric shock and other electrical accidents, while mechanical safety stipulates the mechanical mechanism, operating parts, etc. of electrical equipment. Safety requirements to ensure that the equipment will not cause harm to personnel under various circumstances. AndSolar AMCL module-level rapid shutdown device successfully passed the standard, which can effectively ensure the safety of users' electricity consumption in actual operations.

I EC 61000-6-1/-2/-3/-4 :

IEC 61000-6 is an electromagnetic compatibility (EMC) standard. Electronic and electrical equipment will produce electromagnetic fields when they are in operation, which is likely to affect each other. The IEC 61000-6 standard includes a series of EMC tests. and requirements, which are designed to ensure that electrical and electronic equipment can work normally in a variety of different environments without interfering with each other and without being controlled. This standard is widely applicable to various equipment and various environments. It contains four parts, including (1) Electromagnetic Compatibility, General Standard - Immunity for Residential, Commercial and Light Industrial Environments, (2): Electromagnetic Compatibility, General Standard - Immunity for Industrial Environments, (2): Electromagnetic Compatibility, General Standard - Immunity for Industrial Environments, (2) 3): Electromagnetic compatibility, emission standards for residential, commercial and light industrial environments, (4) Electromagnetic compatibility, emission standards for industrial environments. AndSolar AMCL module-level rapid shutdown device has successfully passed the standard and can effectively meet the above EMC requirements.